In an ever-changing world, being at the forefront of innovation and research is critical to the success and growth of any industry. In the aggregates sector, where we are constantly facing new challenges, having a dedicated project team becomes even more essential.

ANEFA’s project team plays a key role in finding solutions and identifying new opportunities for the extractive industry. Its main objective is to lead and coordinate participation in European projects, which represent an excellent opportunity to bring together the public sector, led by universities, and the private sector in the search for innovative solutions. By participating in these projects, a synergy is created that allows combining specialized knowledge, resources, and experiences to face the challenges that our industry will face in the future.

Among its functions is to identify and evaluate calls for European projects related to aggregates and the extractive industry. Defining and searching for partners to form the best possible consortium.

The fundamental role of ANEFA’s project team is to take responsibility for coordinating the activities, resources, and deadlines necessary for the successful development of each project. These collaborations foster knowledge transfer, joint research, and the implementation of practical and sustainable solutions in the aggregates sector.

Participation in European projects not only provides a platform for research and innovation but also strengthens the position of our industry and ANEFA’s position in the international arena. By being involved in large-scale projects and transnational collaboration, we ensure that state-of-the-art knowledge and practices are integrated into our sector. This allows ANEFA to adapt to current changes and challenges, as well as to anticipate and lead the future transformation of the industry.

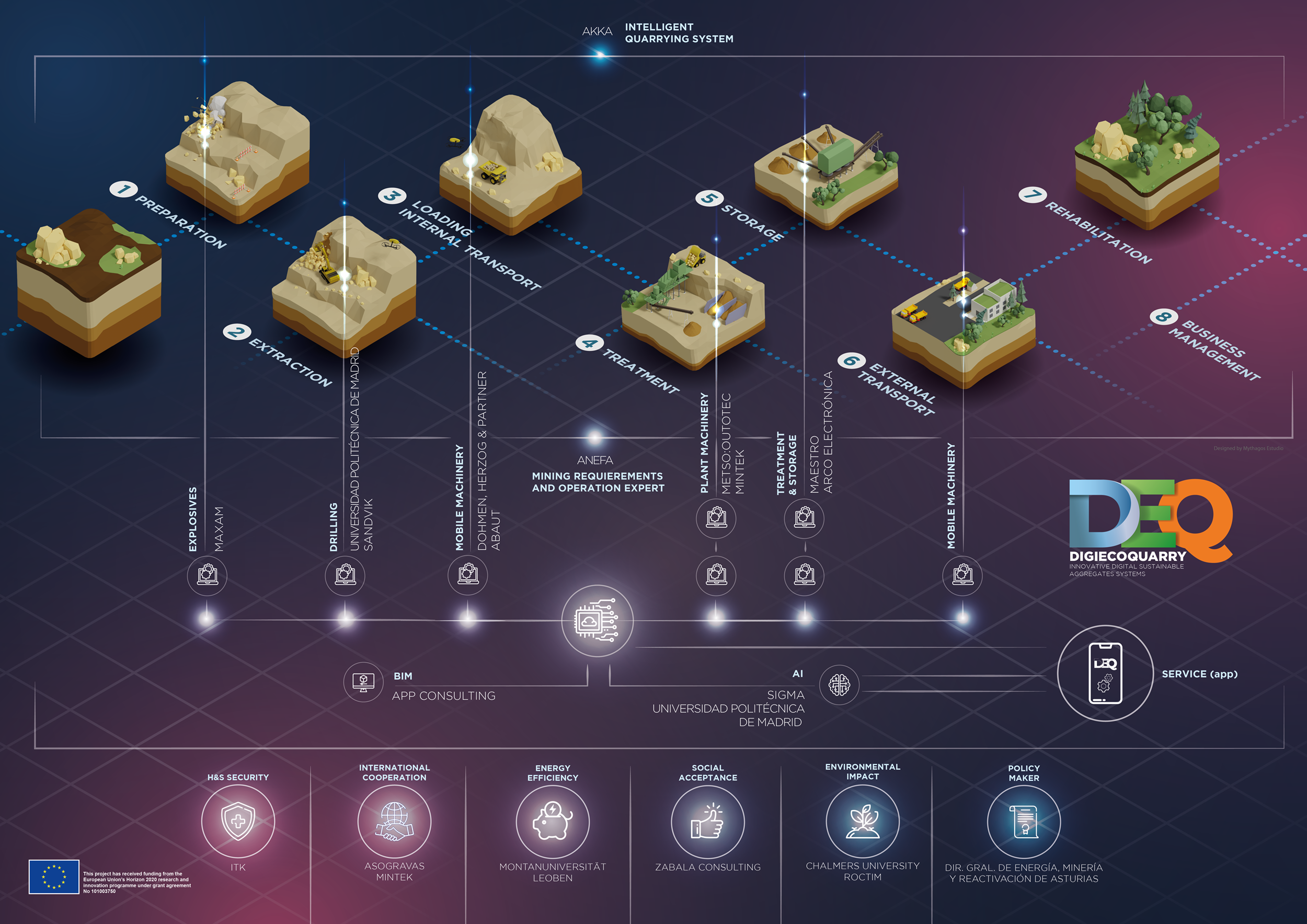

DigiEcoQuarry

www.DigiEcoQuarry.eu

Follow us on our social networks to always be aware of our progress

DigiEcoQuarry is a project funded by the European Union under the Horizon 2020 program (No. 101003750), with the goal of designing, developing, and validating an Intelligent Quarrying System for Quarry Management in five aggregate exploitations. The system, called IQS (Intelligent Quarrying System), is composed of sensors, processes, and tools to capture, store, and process data generated throughout all stages of aggregate production. Once the system is implemented, it will allow integrated, digitized, automatic, and real-time control of the activities carried out in an operation. It will allow the automatic generation of reports and the evaluation of the improvements made in the organization.

The project was born as a solution to two fundamental problems of the European Union: the increase in the consumption of raw materials and its dependence on external supply. DigiEcoQuarry seeks to make mining operations more efficient, safe, energy-efficient, and socially responsible through automation and digitization. The 4-year DigiEcoQuarry consortium consists of 25 international partners and 5 European aggregates companies.

The digitization of the mining operations enables environmental and sustainable management of the mining operations, acting as a driving force in decision-making and process optimization. The organization needs to have a database that allows collecting data from various sources, storing them in an efficient way, and being able to export them to generate the dashboards required by each of the departments. In addition, DigiEcoQuarry seeks to digitize the machinery currently in use on the farm to facilitate and analyze the farm in an efficient way.

Rotate

http://rotateproject.eu/

Follow us on our social networks to always be aware of our progress

Europe is dependent on the import of raw materials, so it is necessary to increase domestic supply to ensure the global competitiveness of its manufacturing industries and accelerate the transition to a sustainable society. Although there are deposits of Critical Raw Materials (CRM) in the EU, many are not exploited due to the environmental impact required to obtain them. The extraction of CRM is associated with high levels of emissions and pollution of air, water, and soil. One possibility for increasing CRM production without opening new mines is to improve the quality of the ore, which would allow the recovery of CRMs that are currently treated as waste.

The sector must move towards a reduction in energy consumption and emissions and sustainable resource management, paying special attention to waste management and water management. Materials characterization and the implementation of digital tools are key to improving efficiency in the management of resources and materials.

The overall objective of the Rotate project is to provide cost-effective and replicable solutions to increase the quality of mined ore, improve the extraction and processing of materials, and ensure sustainable management of resources and materials in the extractive sector. The project also seeks to establish a symbiosis between industry and construction through circular solutions for waste valorization. In addition, it seeks to develop co-creative strategies to improve social acceptance of the extractive sector. It involves 21 entities from nine different countries and ANEFA is the leader and general coordinator of the project.