At ANEFA, our Projects Department leads the innovation that powers Europe’s dual digital and ecological transition. We turn operational and social challenges into measurable competitive advantages—strengthening the resilience, efficiency and sustainability of raw materials supply.

Proven Results

We successfully delivered DigiEcoQuarry, the flagship project that brought full digitalisation and automation to aggregates quarries. Its outcomes show increased net margins, enhanced health and safety, and improved social acceptance of operations—setting a new benchmark for the sector.

Continuous Innovation

We constantly identify new opportunities, prepare competitive proposals, and ensure long-term exploitation of project results. Our mission is clear: lead the next generation of sustainable mining in Europe.

Our Vision

We see the extractive industry as a guarantor of the resources Europe needs for a clean, climate-neutral future.

We promote responsible innovation, strong community relations, and sustainable production models that reinforce the sector’s competitiveness.

At ANEFA, we don’t just meet expectations—we lead the transformation of mining into a more digital, circular, and socially trusted industry.

Active Projects: Circularity, CRMs, and social license to operate

We are currently leading three initiatives that address the sector’s most critical challenges:

SCIMIN-CRM focuses on harnessing the immense potential of more than 100,000 Mining Waste Facilities (MWFs) in Europe to access Critical Raw Materials (CRMs). We are developing a “fast-path” process and a collaborative digital platform for smart evaluation.

Rotate is centered on achieving zero emissions and zero pollution by promoting the circular economy through waste valorization — such as reusing aggregates washing residues for construction.

RM SLO PLUS Hub addresses the critical need for a social license to operate, creating training and consultancy tools to mitigate social risks and ensure transparency.

Continuous Innovation and Strategic Exploitation

Our commitment is dynamic. The department is constantly seeking new opportunities and is actively engaged in drafting new project proposals. We maximize the exploitation of project results to ensure the sustainability and long-term impact of solutions within the EU’s extractive sector.

In summary, we view the extractive industry as a guarantor of the resources we need, advancing clean production and transforming social management (SLO) into a competitive advantage. Our department is your assurance that ANEFA not only complies but leads the next generation of sustainable mining.

SCIMIN

Turning Waste into Essential Resources for Europe

https://scimin.eu

Follow us on our social networks to always be aware of our progress

The SCIMIN-CRM project is a key initiative led by ANEFA to address Europe’s strong reliance on imported raw materials.

Currently, the recovery of valuable materials from Mining Waste Facilities (MWFs) is practically nonexistent, despite the estimated presence of more than 100,000 such facilities with vast untapped potential. Our main objective is to reverse this situation by increasing access to primary and secondary raw materials through the valorization of these resources.

To achieve this, we are developing a standardized and transferable methodology known as the fast-path, which will significantly reduce the time required to assess the feasibility of these facilities by 83%. This fast-path method, designed for operators and public administrations, will provide a clear roadmap for evaluating the technical, economic, environmental, and social feasibility of waste reprocessing.

A key element of this methodology is the creation of the SCIMIN-CRM Digital Platform, an integrated, collaborative tool that centralizes the consortium’s collective knowledge and experience. The platform will include modules for feasibility assessment, real-time monitoring, and social awareness guidelines.

We will validate this comprehensive process through four pilot projects in Spain, Sweden, Austria, and Bosnia and Herzegovina. These sites are developing and testing new technologies for the recovery of Critical Raw Materials (CRMs) such as fluorite, barite, Rare Earth Elements (REE), and bauxite/aluminum, as well as high-value non-critical materials such as aggregates.

Our approach ensures that resource recovery is carried out under the highest sustainability standards, prioritizing the minimization of hazardous substances, environmental performance, and biodiversity restoration — while also fostering the social acceptance of these operations.

By the end of the project in 2028, we aim for this new process to become the industry standard for the sustainable management and reassessment of mining waste facilities, contributing to Europe’s long-term circularity and competitiveness.

Rotate

http://rotateproject.eu/

Follow us on our social networks to always be aware of our progress

Rotate is a European-Union-funded research and innovation project (under the Horizon Europe programme) that seeks to deliver environmentally sound and industrially replicable solutions across the mining and quarrying sectors. Its focus is on enhancing circularity, valorizing waste streams, reducing environmental impacts, and securing a sustainable supply of critical raw materials for European industry.

Key aims

The project sets out four main ambitions:

• Cut-off grade reduction – Lower the threshold (“cut-off grade”) at which critical raw materials become economically viable to extract in open-cast mines and quarries.

• Eco-friendly extraction & processing – Minimize environmental footprint (emissions, resource consumption, materials usage) during extraction and processing in open-cast operations.

• Circularity – Deliver circular economy solutions by valorizing solid and sludge wastes, creating synergies between critical raw materials, aggregate industries, and construction.

• Social acceptance – Provide co-creative strategies to enhance the social license to operate of open-cast extractive industries by engaging stakeholders, interacting with policy, and building networks.

Why it matters

The project addresses the twin challenge of meeting Europe’s demand for critical raw materials (for clean technologies, batteries, etc.) while ensuring extraction and processing become more sustainable and circular.

It aligns directly with European policies on raw materials, circular economy, and sustainability (including meeting UN Sustainable Development Goals) and supports the transition to a greener industry.

By combining industrial, academic, and policy actors across many countries, the project aims for replicable and scalable solutions rather than net-new pilots with no pathway to market.

Implications for the Extractive Industry and Beyond

For the aggregate and mining industries, ROTATE offers pathways to lower cut-off grades, meaning that more material (including lower-grade ore or by-products) becomes economically recoverable, potentially reducing waste.

The emphasis on circularity means waste streams are treated as potential feedstocks: this can reduce disposal needs, reduce environmental impact, and open new value streams (e.g., waste from quarrying used for new materials).

The digital monitoring component supports smarter production: real-time data on emissions, energy, and equipment performance can lead to improved operational efficiency and environmental compliance.

The focus on social acceptance recognizes that industry’s future depends on societal license and regulatory support: by proactively engaging communities and stakeholders, the project seeks smoother operations and fewer conflicts.

Overall, Rotate contributes to the transition from linear extractive models (take-make-dispose) to sustainable, circular, and resource-efficient value chains.

RM SLO PLUS Hub

Building Trust for the Extractive Industry

https://slohub.org

Follow us on our social networks to always be aware of our progress

The raw materials sector is essential to the European economy and underpins the digital and green transition currently underway. However, opening or managing operations often faces significant challenges, such as local community opposition, leading to delays or even the cancellation of critical projects.

To overcome this barrier, the industry must obtain and maintain the Social Licence to Operate (SLO) — the ongoing level of acceptance and trust granted by communities and stakeholders to an operation.

The RM SLO PLUS Hub is a transformative initiative led by a multidisciplinary consortium of experts aiming to establish a centre dedicated to developing training and consultancy tools. Our goal is clear: to close communication and expectation gaps between resource operations and society, fostering responsible dialogue and improving transparency and trust in the industry.

As a partner with extensive experience in the sector and in resolving SLO-related conflicts, ANEFA contributes industrial expertise and governance knowledge to ensure that the Hub’s solutions are practical and effective in real-world contexts.

The Hub will act as a central repository of best practices in SLO, offering specialised training programmes tailored to the needs of various stakeholders — from large companies and SMEs to policymakers, local communities and NGOs. These programmes will cover essential principles such as transparency and shared value creation, while also offering strategic consultancy services to help companies develop their own community engagement strategies and comply with sustainability regulations, including ESG principles.

By providing this cross-cutting knowledge, the Hub will directly help mitigate social risks and build a more stable, sustainable and socially accepted raw materials supply chain across Europe.

DigiEcoQuarry

www.DigiEcoQuarry.eu

Follow us on our social networks to always be aware of our progress

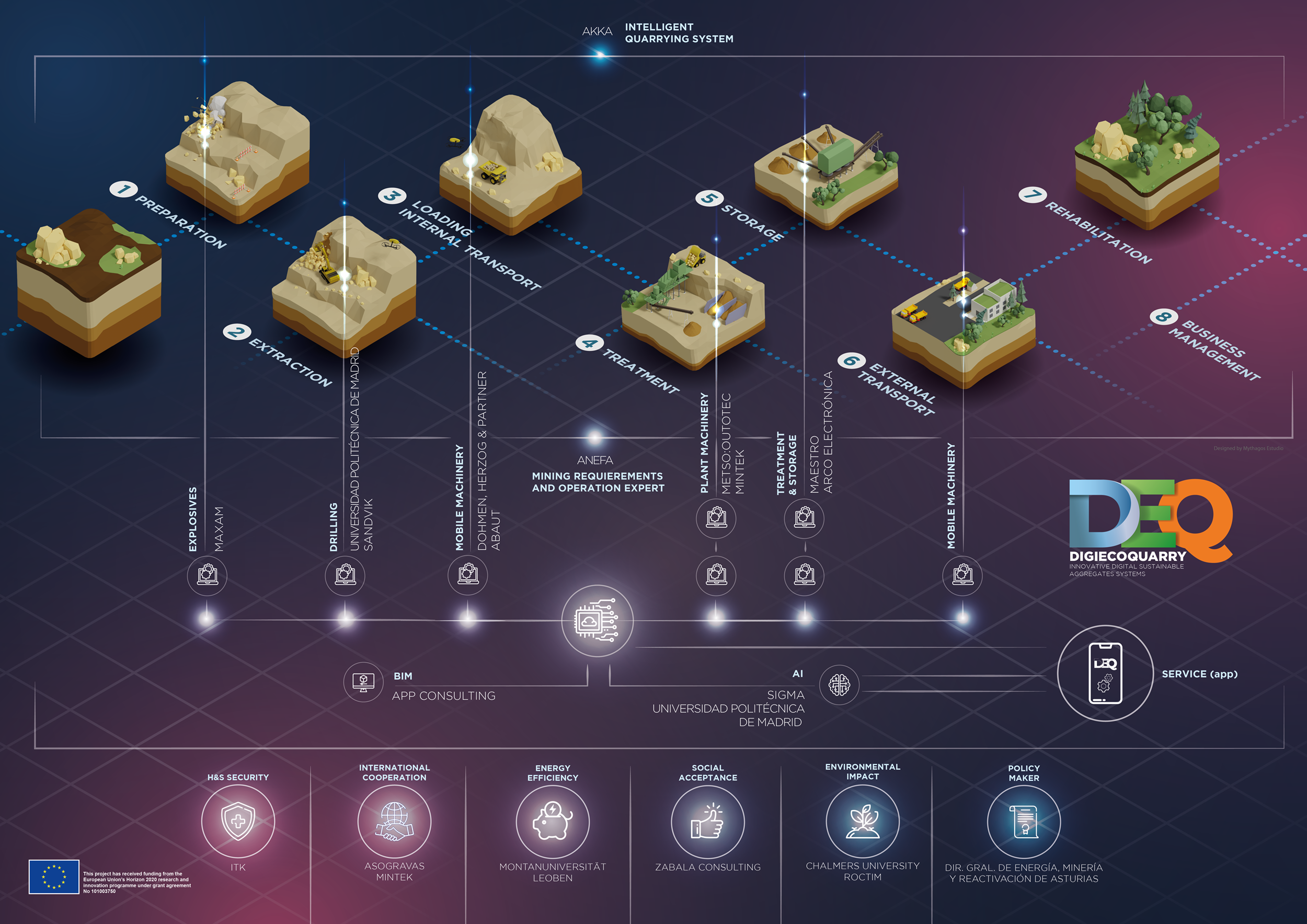

DigiEcoQuarry is a project funded by the European Union under the Horizon 2020 program (No. 101003750), with the goal of designing, developing, and validating an Intelligent Quarrying System for Quarry Management in five aggregate exploitations. The system, called IQS (Intelligent Quarrying System), is composed of sensors, processes, and tools to capture, store, and process data generated throughout all stages of aggregate production. Once the system is implemented, it will allow integrated, digitized, automatic, and real-time control of the activities carried out in an operation. It will allow the automatic generation of reports and the evaluation of the improvements made in the organization.

The project was born as a solution to two fundamental problems of the European Union: the increase in the consumption of raw materials and its dependence on external supply. DigiEcoQuarry seeks to make mining operations more efficient, safe, energy-efficient, and socially responsible through automation and digitization. The 4-year DigiEcoQuarry consortium consists of 25 international partners and 5 European aggregates companies.

The digitization of the mining operations enables environmental and sustainable management of the mining operations, acting as a driving force in decision-making and process optimization. The organization needs to have a database that allows collecting data from various sources, storing them in an efficient way, and being able to export them to generate the dashboards required by each of the departments. In addition, DigiEcoQuarry seeks to digitize the machinery currently in use on the farm to facilitate and analyze the farm in an efficient way.